Buying the Ideal Engine Piston: The Whats and Hows of Engine Pistons

Familiar with the inner workings of an internal combustion engine? If not, here’s a helpful refresher course. Power is produced when the mixture of air and fuel is combusted in the engine cylinder. This pushes down a piston in the cylinder bore, which in turn is connected to the crankshaft with a connecting rod. The linear up and down movement of each piston turns the crankshaft, which is connected to the clutch and gears. These are tasked to turn the wheels. The faster the pistons move, the more power they transfer to the wheels, and the faster the car goes.

These are the basics of every combustion engine. Stock engines undergo a lot of R&D before manufacturers finally put out their products. That’s why we get the usual 7 to 8 years between car model updates. Enough time for a little tinkering to get the best out of the car.

Car enthusiasts, rebuilders, and anyone with more speed in mind, will always want more power. Changing out the engine internals is where to look. Parts that are better built and designed, and made of stronger materials will definitely perform better. A good place to start is with the engine pistons.

What are Pistons?

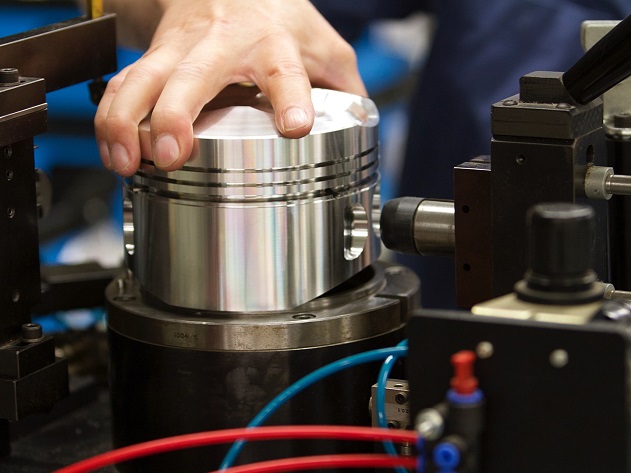

An engine piston is the metal component tasked to be battered from the explosion in each combustion cycle. This is when air is sucked into the cylinder head inlet valve, mixed with fuel from the injectors and ignited by a spark plug. The resulting pressure acts on the piston crown, the uppermost piston part which elongates into the piston skirt. These parts make up the piston body. To ensure that the piston doesn’t seize in the cylinder bore (and to allow for proper compression), the skirt has grooves fitted with compression and oil rings. The rings seal the piston in the cylinder bore, contracting or expanding with changes in temperature and compression. Below this is the cut-out for the wrist pin that slots the top part of the connecting rod.

What do Pistons do?

The role of pistons is to convert the heat from combustion into mechanical force that acts on the crankshaft. It does this in stages, or more precisely, strokes. In a four-stroke engine, and the majority of vehicles, these are the intake, compression, combustion and exhaust strokes. During the intake stroke, the piston moves down the cylinder bore, from its highest position, called the top dead centre (TDC), to its lowest point, the bottom dead centre (BDC). As it does this, it creates a vacuum that forces the air and fuel mixture into the cylinder head, with the intake valve(s) open. It then moves upwards into the compression stroke, towards the TDC, with both intake and exhaust valves closed. This compresses the air and fuel mix. At the end of the compression stroke, a spark plug ignites the air fuel combination creating an explosion. This is the power stroke. The rise in pressure forces the piston down the cylinder bore, and since it is joined to a connecting rod, this turns the crankshaft journal. Both valves remain closed, until the piston again makes its way to the TDC to remove the remaining gases out through the exhaust valve in the exhaust stroke. The complete cycle is repeated over and over again, thousands of times a minute.

Can Pistons Fail?

Repairing and replacing faulty pistons on time can save an engine from complete ruin. Not all pistons will endure the excessive force that acts on them in each engine cycle. There can be minor or severe damage to the piston or individual parts, which also pinpoint other engine problems. There can be visible damage to the piston crown, with increased engine noise, loss of power and misfiring the common signs. Damage to the skirt results from poor engine maintenance and causes knocking, piston slap and ultimately piston (and engine) seizure. This can shred an engine to pieces. Then there are faults with the piston rings. Large amounts of unburnt fuel in the form of white or grey smoke form the exhaust, sudden loss of power and an overheating engine are signs of worn oil and compression rings. During such instances, it’s also common to find damage to cylinder walls, the intake and exhaust valves, the piston wrist pin and other parts.

Replacement Options

Not all pistons are created equal. Though cast iron was the go-to material in the past (for the perceived strength), an engine piston today in made from aluminium and traces or other materials, particularly silicon) that better handle the constant expansion and contraction of the piston during each cycle. Silicon content varies. In performance aftermarket pistons, this is lower. For stock pistons, the higher silicon content offers better sealing and reduced vibrations. The engine is quieter, though not necessarily any faster.

If you looking for more performance, then you can replace your cast pistons with forged or billet pistons. These are much stronger with the aluminium forged from a previously pre-formed mould. The final version is then machined to perfection. Even stronger are billet pistons, essentially carved out of a single piece of aluminium, often using high-tech CNC machining. Billet pistons are also the most expensive, featuring in one-off racing cars. For most people, a good trade-off between price and performance are forged pistons. These can take the faster engine speeds, heat and pressure without leaving a dent in your pocket.